Turbo Mill model E, R & CR

❖NEW PRODUCT❖ 『Multi-cooling System TURBO MILL』

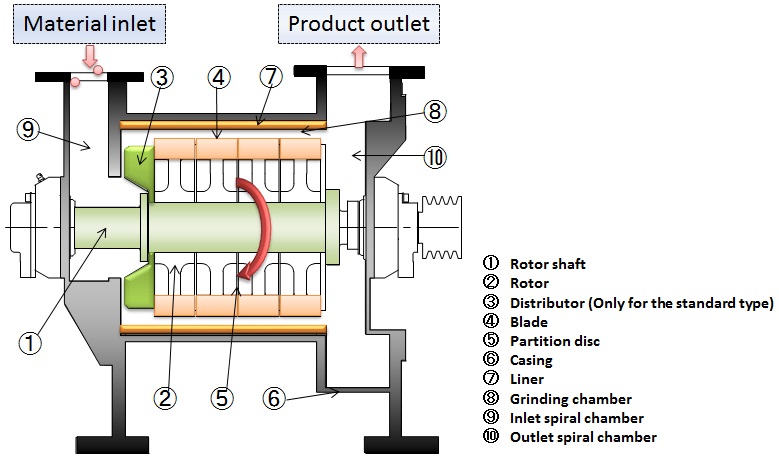

GRINDING PRINCIPLE

A ultra-fine grinding machine by means of vortex airstream. Ultra-fine grinding is done by mechanical impact of rotating blades as well as intensive vortex airstreams and high frequency of air pressure oscillation generated at the backside of rotating rotor and the groove slopes.

This mill can grind heat-sensitive materials without damage as grinding takes place in the airstream that can take heat away.

❖ MACHINE STRUCTURE & MATERIAL FLOW

Material is taken into the mill being carried by airstream. The airstream containing material is given spiral motion in the inlet spiral chamber⑨ and transmitted evenly into the grinding chamber. Grinding takes place between rotor blades④ and liners⑦ by mechanical impact, intensive vortex airstream and high frequency of air pressure oscillation, and after that the ground product is taken out through outlet vortex chamber⑩ carried by airstream.

CHARACTERISTICS

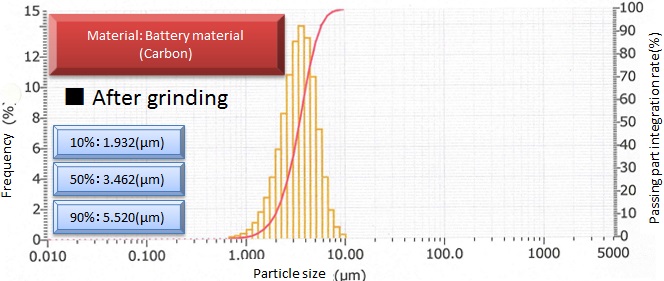

- Sharp product particle size distribution 【Product side range: d50= 3 to 50 micron meter】

Product contains very few percentage of excessively fine part and its particle size distribution curve is very sharp.

❖ Application example by Model T400 RS

・Battery material(Carbon)【Particle size before grinding: d50=ca.600 micron meter】

⇒ After grinding (by 1 pass)【Product size: d50=3.46 micron meter】

- Efficient removal of grinding heat

Airstream takes the heat generated by grinding from the product and thus heat-sensitive materials like toner can be well ground. - Low running costs

Much lower running costs in comparison with those by a jet mill. - Continuous long running possible

Design for long time continuous trouble free operation without heavy maintenance. - Easy machine cleaning

Mill casing is designed consisting of 2 parts which are fixed together at an angle of 45 degree and is possible to open the upper one so as to enable to clean inside the chamber with ease.

- Various derivative machine types (❖ To meet various requirements we have a number of derivative types like type S (Standard), type M,

type E and type R to obtain from coarse to fine products.)

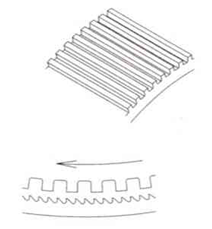

Type Type E (EL) (ES) (EX) Number of rotors 4 4 8 Number of grooves 56×4 112×4 112×8 Gaps size between rotor & liner(mm) 2~3 Anti-abrasion specifications Induction hardening

Hard chrome plating

WC chip brazing

Induction hardening

Hard chrome plating

Insert type blade in special steel Blade & liner shapes

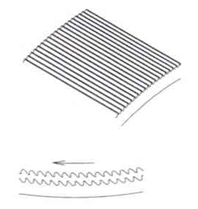

Type Type RS Type RSS Number of rotors 4 4 Number of grooves 300×4 400×4 Gaps size between rotor & liner(mm) 1~2 0.7~2 Anti-abrasion specifications Special electro-plating

Blade & liner shapes

For ultra-fine grinding

●Toner

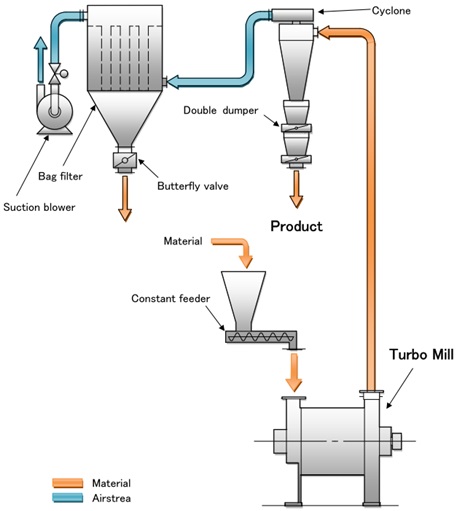

STANDARD SYSTEM FLOW

APPLICATIONS

- ChemicalsPolyethylene, Phenol resin, PVC, Epoxy resin, PC, ABS, AS, Urea formaldehyde resin, PVA,

Powder coating, Toner, Carbon, Lime stone, Coal, Pigment, Gypsum, Cellulose, Superabsorbent polymer, Copper powder, Cerium oxide, Wax, CMC, Melamine resin, - FoodsWheat, Rice, Corn, Sugar, Granulated sugar, Salt, Spice, Fish meal, Seaweed, Gelatin, Agar, Buckwheat, Buckwheat chaff, Tea leaves, Bran, Prawnf, Dried noodle, Red pepper, Sodium alginate

- PharmaceuticalsChinese medicine (Licorice), Sorbitol, Glucose

- Miscellaneous materialsWood powder, Pulp, Paper, Old paper, Rice husk

❖ EXAMPLES OF GRINDING DATA

| Industry sector | Material sort | Material size | Product size | Mill type |

Throughput (kg/h) |

| Electric & electronic Materials | Graphite | d50=450μm | d50=12μm | T400-4J | 300 |

| Battery materials ca. | few 10s micron m(Agglomerates) | d50=2μm | T400-4J | 250 | |

| Paint & pigment | Toner | d50=250μm | d50=6.5μm | T400-4RSJ | 45 |

| Toner | d50=190μm | d50=5.3μm | T400-4RSSJ | 25 | |

| Toner (Medium size grinding) | 1~4mm | d50=25μm | T400-4J | 100 | |

| Toner | d50=580μm | d50=5.9μm | T400-3CRSJ | 85 | |

| Powder coating | 5~20mm(Flakes) | d50=30μm | T400-3ELJ | 300 | |

| Paint dregs | d50=1.5mm | d50=10μm | T400-4J | 300 | |

| Pigment | d50=100μm | d50=6μm | T400-4J | 60 | |

| Salt | d50=500μm | 100%<75μm | T400-4J | 500 | |

| Foods | Pregelatinized starch | d50=90μm | d50=50μm | T400-4J | 250 |

| Rice | 2~3mm | 80%<63μm | T400-4J | 350 | |

| Buckwheat chaff | Half cracking | d50=180μm | T400-4J | 60 | |

| Granulated sugar | 1×1×1mm□ | 100%<75μm | T400-4J | 500 | |

| Sodium alginate | d50=50μm | d50=15μm | T400-4ESJ | 150 | |

| Red pepper | 20~50mm | d50=190μm | T400-4J | 500 | |

| Animal feeds | Fish bones | Max4mm | d50=30μm | T400-4J | 150 |

| Defatted soybeans | d50=85μm | d50=10μm | T400-4J | 200 | |

| 脱脂糠 | d50=300μm | d50=12μm | T400-4RSJ | 80 | |

| 鉱産物 | 軽質炭酸カルシウム | Max10mm | d50=50μm | T400-4EXJ | 800 |

| 石灰石 | d50=180μm | d50=10μm | T400-4J | 650 | |

| 石灰石 | d50=180μm | d50=5μm | T400-8MJ | 270 | |

| 石灰石 | d50=180μm | d50=3μm | T400-4ESJ | 150 | |

| 医薬 | 漢方薬 | Max5mm(繊維状) | 70%<150μm | T400-4J | 300 |

| ソルビット | Max2mm | 99%<180μm | T400-4J | 300 | |

| ブドウ糖 | 1~2mm | 99%<75μm | T400-4J | 200 | |

| 樹脂 | LDPE | 2~3mmペレット | 90%<177μm | T400-4J | 60 |

| ABS | 2~3mmペレット | 95%<210μm | T400-4J | 70 | |

| PET | Max5mm | 93%<105μm | T400-4J | 130 | |

| PVC(硬質) | Max8mm | 95%<500μm | T400-4J | 60 | |

| CMC | d50=105μm | 70%<75μm | T400-4J | 50 | |

| セルロース | 5~10mm | d50=40μm | T400-4J | 60 | |

| フェノール樹脂 | Max5mm | d50=18μm | T400-4J | 550 | |

| フッ素樹脂 | Max30mm(フレーク) | d50=30μm | T400-4J | 200 | |

| メラミン樹脂 | 1~10mm | 99%<75μm | T400-4J | 250 | |

| 吸水性ポリマー | 2~3mm | d50=2μm | T400-4J | 100 | |

| 化学 | 活性炭 | d50=200μm | d50=20μm | T400-4J | 350 |

| 酸化セリウム | 2~3mm(凝集塊) | d50=0.5μm | T400-4J | 150 | |

| ワックス | d50=16μm | d50=6μm | T400-4RSJ | 65 | |

| コークス | d50=75μm | d50=15μm | T400-4J | 150 | |

| 難燃剤 | d50=20μm | d50=4.2μm | T400-8MJ | 180 | |

| その他 | 木粉 | 1~3mm | d50=150μm | T400-4J | 100 |

| パルプ(古紙) | 1~10mm | 開綿状 | T400-4J | 200 |

標準型仕様

| 型式 | T250 | T400 | T600 | T800 |

|---|---|---|---|---|

| 粉砕室内径(mm) | 250 | 400 | 600 | 800 |

| 最高回転数(min-1) | 12,000 (11,000) |

7,500 (8,000) |

5,200 (5,600) |

4,100 |

| 電動機(kw) | 11~15 | 30~37 | 55~75 | 90 |

| 処理能力比 | 0.3~0.5 | 1 | 2 | 3 |

(括弧)内はCR型の場合を示す。

Multi-cooling System TURBO MILL New!

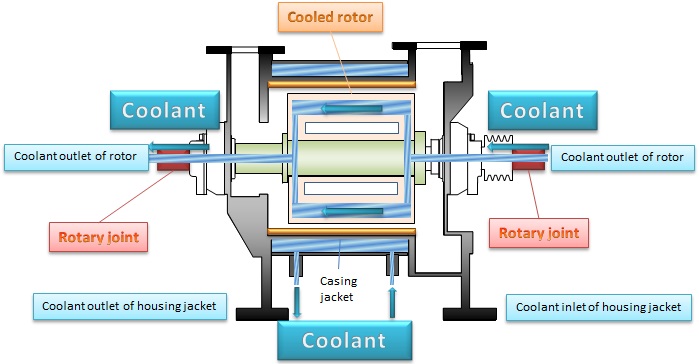

❖ Turbo Mill type CRS(S) with cooled rotor

SECTIONAL DRAWING

❖ ポイント

- 遠心力に対する流体のコントロール

- 熱交換率の高い流体の流し方

- アンバランスを発生させない構造設計

- 高速対応のロータリージョイント

CHARACTERISTICS

- Specially designed coolant channel to achieve effective heat removal.

- Doubled throughput compared with conventional type without cooled rotor.

- Even smaller product particle size can be obtained.

- In case of new machine installation considerable costs down is possible with smaller cooling utilities.

- Capable of grinding of heat-sensitive materials like toner and powder coating

- Cooled rotor can be retrofitted on a existing mill with non-cooled rotor.

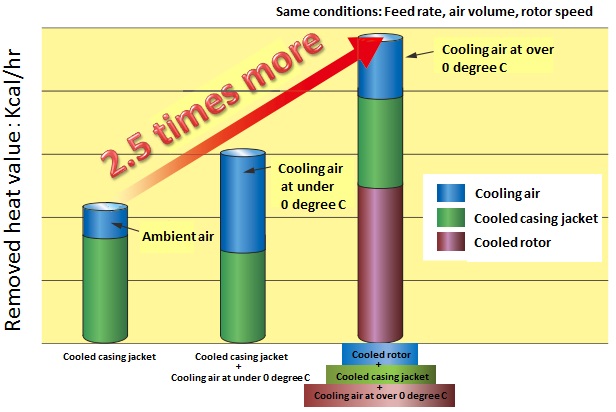

Comparison graph of heat removal between the mills with cooled and uncooled rotors (by model T400-CRS).

- 『ローター冷却』+『ジャケット冷却』+『プラス冷風』の3倍冷却方式にて

当社比2.5倍以上の冷却効果!

- Cost cutting is possible by replacing a big capacity air-cooler to cool down air under 0 degree C with smaller one, as the heat removal efficiency of 1.3 times higher with this system in our internal tests result by both jacket cooling, rotor cooling and air cooling sat over 0 degree C.

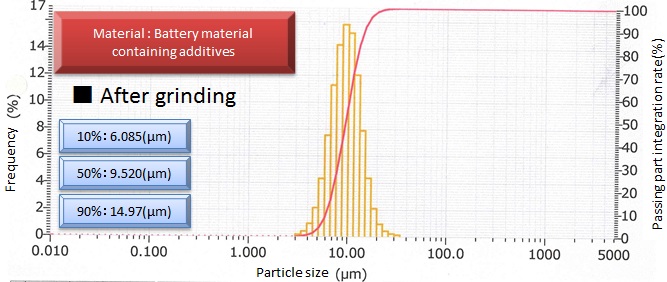

❖ EXAMPLES OF GRINDING DATA 1) : by model T400 CRS

・原料:電池材料(添加剤入)【粉砕前原料粒度:d50≒78.1μm】

⇒ 粉砕後(1Pass) 製品粒度:d50=9.520μm

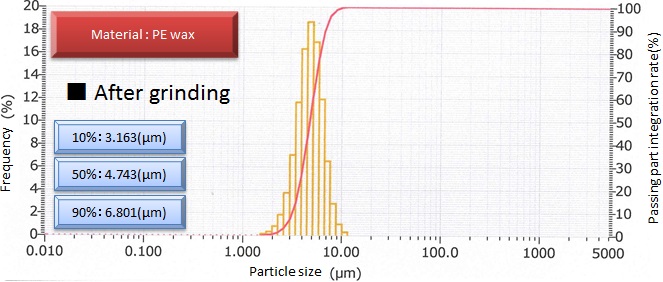

❖ EXAMPLE OF GRINDING DATA 2) : by model T400 CRS

・Material : PE wax 【Material size before grinding : d50=7,1 micron meter】

⇒ Product size after grinding (by one pass) : d50=4.73 micron meter

AVAILABLE MODEL FOR MULTI-COOLING SYSTEM

| Model | T250 | T400 | T600 | |||

| Rotor type | E | RS | E | RS | E | RS |

| Inner dia. of grinding chamber[mm] | φ250 | φ400 | φ600 | |||

| Max.rotor speed[min-1] | 8400 | 11000 | - | 8000 | - | 5600 |

| Motor[kW] | 11~15 | 30~37 | 55~75 | |||

TEST IMPLEMENTATION PROCEDURE

Upon receipt of customer's application forms with the test details we will discuss their present problems so as to achieve the aimed test results by proper selection of test machines and its operation conditions.

info@freund-turbo.co.jp

Air-stream pulveriser by means of high speed vortex and high pressure frequency generated by high speed rotor specially designed to obtain extremely fine products.

CHARACTERISTICS

- Sharp distribution of product particle size

By means of high speed vortex product particle size of singleμm range can be obtained. - Effective grinding heat removal

Through grinding by high speed air-stream and vortex grinding heat can effectively be reduced, by which heat sensitive products like toner can be ground. - Lower running costs

Comparing with conventional impact mill Turbo Mill can be operated with much lower energy consumption. - Suitable for long time continuous operation and for mass production

Turbo Mill is robustly designed for stable long time trouble free continuous operation with low maintenance requirements. - Wide range of application

Turbo Mill can be applied to extensive field of industries like chemical, food and pharmaceutical, etc.

STANDARD SPECIFICATIONS

| TYPE | T250 | T400 | T600 | T800 |

|---|---|---|---|---|

| Chamber inner diameter (mm) | 250 | 400 | 600 | 800 |

| Max. rotor speed (r/min) | 12,000 (11,000) |

7,500 (8,000) |

5,200 (5,600) |

4,100 |

| Motor(kw) | 11~15 | 30~37 | 55~75 | 90 |

| Compared throughput ratio | 0.3~0.5 | 1 | 2 | 3 |

| Number of rotors | 1~4 | 1~4 (2~8) |

1~4 (2~8) |

1~4 (2~8) |

Data in parentheses are those of model CR